Product is Auction

Product is Auction

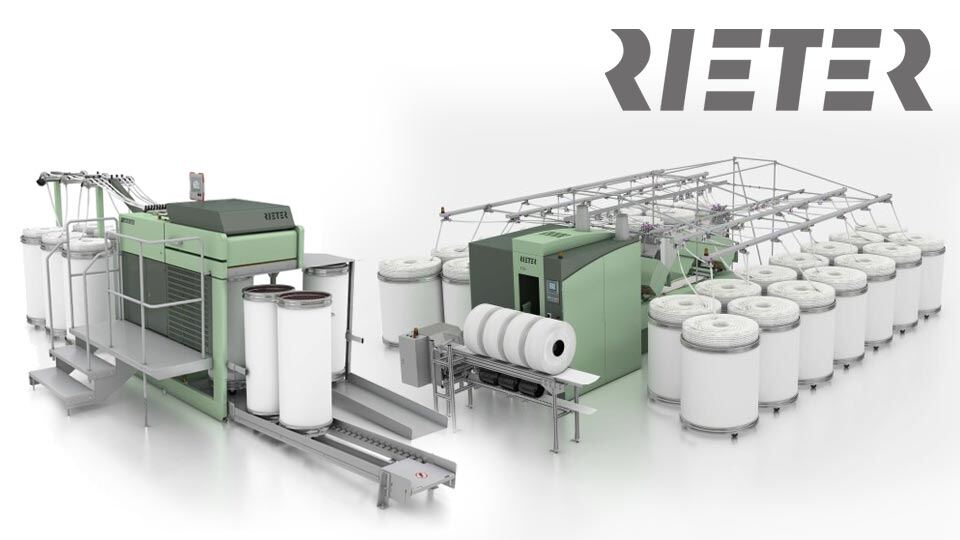

2005 Rieter Rietex J0/10 Spinning system

Various Yarn ManufacturingSKU: SSMINYO1-00000365

CD300 Winders. HPC texturation and update in 2015, The system runs over several floors / Consisting of: Draw frame / Blowing shaft;